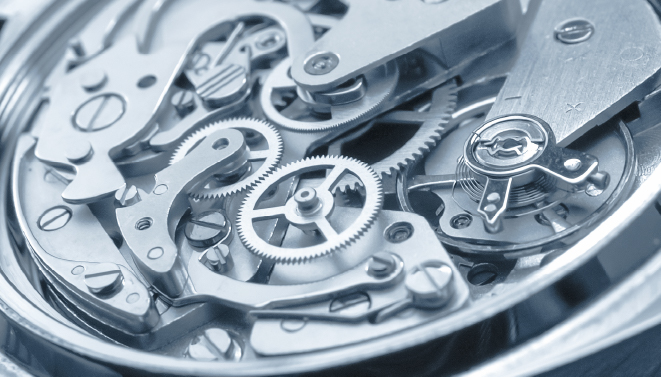

In turning operations with fixed headstock lathes, it is essential to pay attention to every installation detail in order to minimise vibrations and preserve machining quality.

The generation of vibrations cannot be completely avoided, but it is possible to keep them under control by acting on specific influencing factors: from the choice of peripherals to the correct positioning of the fixed headstock lathe and bar feeder that make up the installation.

In particular, the bar feeder selected to work alongside the fixed headstock lathe must be optimised in every aspect. Not only the bar guiding system, but also the installation distance between lathe and bar feeder plays a decisive role in limiting vibrations and ensuring stability, precision, and efficiency.

Why Does Installation Distance Affect Vibrations?

The space between the lathe and the bar feeder has a direct impact on the stability of the entire process.

If the bar feeder is positioned too far from the lathe spindle, the unsupported bar length increases, requiring additional support to prevent deflection and oscillation during rotation. This effect is amplified when working with long bars, as is often the case with fixed headstock lathes.

The generation of harmful vibrations, transmitted to the tool and the workpiece, compromises the surface finish quality, reduces cutting edge life, stresses and damages the spindle, and increases noise levels in the workshop. All of this leads to a loss in overall efficiency and productivity.

This is why it is essential to position the bar feeder precisely, ensuring optimal distance and accurate alignment with the spindle axis. A well-calibrated installation distance reduces unsupported bar length, improves stability during rotation, and ensures smooth and precise bar feeding—even in the most demanding operations.

MAESTRO: The Shortest Installation Distance on Fixed Headstock Lathes

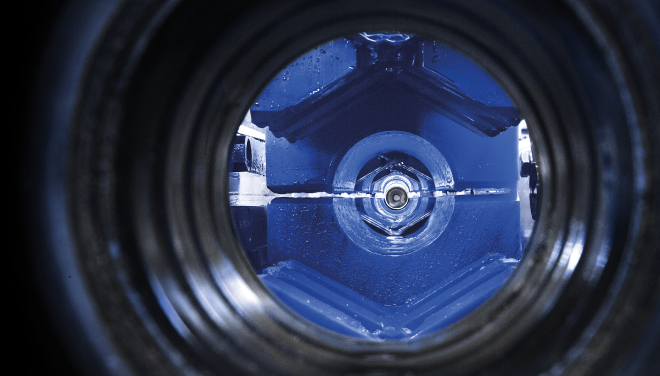

The IEMCA MAESTRO bar feeder was designed with exactly this goal in mind: to minimise the installation distance between the bar feeder and the fixed headstock lathe, ensuring optimal support for the bar throughout the machining process.

Thanks to the guide channel design which integrates the ABACOS system, MAESTRO allows the use of short bar pushers, significantly reducing the distance between the bar feeder and the lathe compared to traditional solutions.

With MAESTRO, you get:

- Minimised vibrations

- Higher precision and surface finish quality

- Extended lifespan of spindle and tools

Precision and Stability on Fixed Headstock Lathes Starts with Installation Distance

Choosing a bar feeder that allows for a reduced and optimised installation distance, such as IEMCA MAESTRO, is a strategic move for those working with fixed headstock lathes and aiming for productivity, reliability, and consistent quality.

Want to find out how MAESTRO can adapt to your fixed headstock production setup? Contact us now