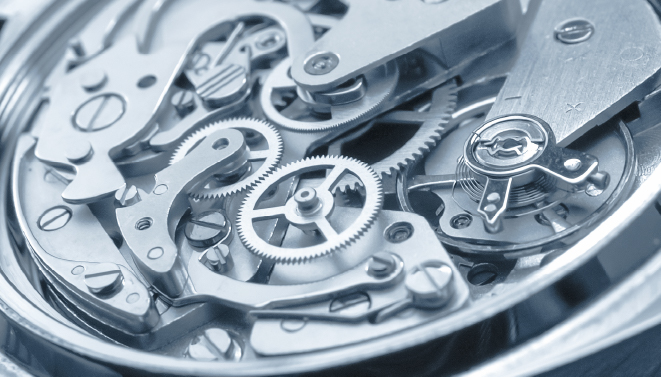

One of the most challenging aspects of turning with fixed headstock lathes is the management of vibrations: knowing how to control and minimise them is essential to ensure maximum quality and precision in machining.

If not properly controlled, vibrations can compromise the surface finish of the part, reduce the tool life, generate spindle stress and, in general, negatively affect the entire production process.

Every detail of the ecosystem of peripherals that support the fixed headstock lathe can make a difference. When it comes to the bar feeder, it is important to evaluate the features of the bar guiding system and the installation distance from the lathe. But there is another key factor that plays a decisive role in the stability and precision during the machining cycle: the structure of the bar feeder.

Why the Bar Feeder Structure is Key to Reducing Vibrations

In machining with fixed headstock lathes, the structural rigidity of the bar feeder is a crucial element for keeping vibrations under control. Especially when working with long bars, even minimal deflection or instability can generate vibrations that propagate to the tool and the workpiece, compromising quality and precision.

A robust structure, designed to ensure maximum rigidity, directly contributes to reducing stress. A reinforced central body, a solid base and a stable floor anchoring are all elements that enhance the system’s ability to absorb and dampen vibrations.

The structure of the bar feeder must ensure a controlled dynamic behaviour, capable of protecting the machine-tool-workpiece system during every phase of machining. The more robust and stable the bar feeder structure is, the more the entire installation is able to maintain precision, efficiency, and reliability over time.

MAESTRO: Solid Structure for Maximum Stability During Machining

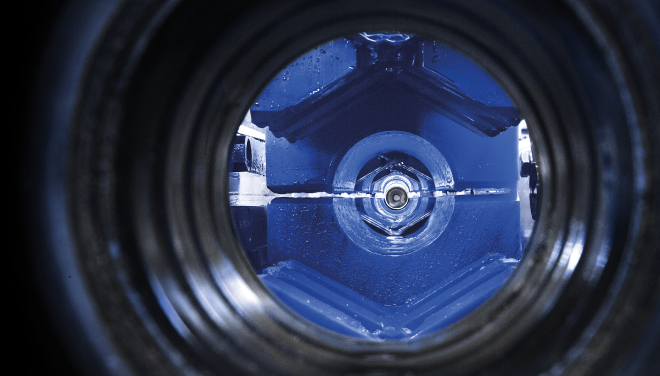

In addition to the flexible bar guiding system and the optimised installation distance, the IEMCA MAESTRO bar feeders stand out for their extremely robust structure, designed to offer maximum stability in machining on fixed headstock lathes.

Every structural component of the MAESTRO bar feeder is engineered to minimise vibrations. Like all IEMCA bar feeders, MAESTRO is built according to the principles of the Heavy Duty platform, which includes additional reinforcement of the lower part of the frame. The central body of the feeder consists of an extra-rigid beam.

Thanks to this extremely robust structure, MAESTRO actively contributes to:

- Absorbing up to 60% of the vibrations generated by the rotating bar;

- Providing a higher level of robustness and stability;

- Protecting the lathe spindle from harmful stresses;

- Ensuring high performance over time.

Robustness and Stability for Maximum Precision on Fixed Headstock Lathes

MAESTRO is designed to offer robustness and stability in machining with fixed headstock lathes, and to minimise vibrations thanks to its extremely rigid structure.

The result? Vibrations under control, better surface finish, longer tool life, reduced spindle wear, and high performance even when using bars that are not perfectly straight.

Find out how MAESTRO can help you achieve a higher level of precision and efficiency in fixed headstock operations: contact us now.