VIRE packaging machines are engineered to deliver maximum versatility, supporting the packaging of both open diapers and adult pants. This flexibility allows manufacturers to effectively meet the needs of a market defined by a wide variety of formats and specifications.

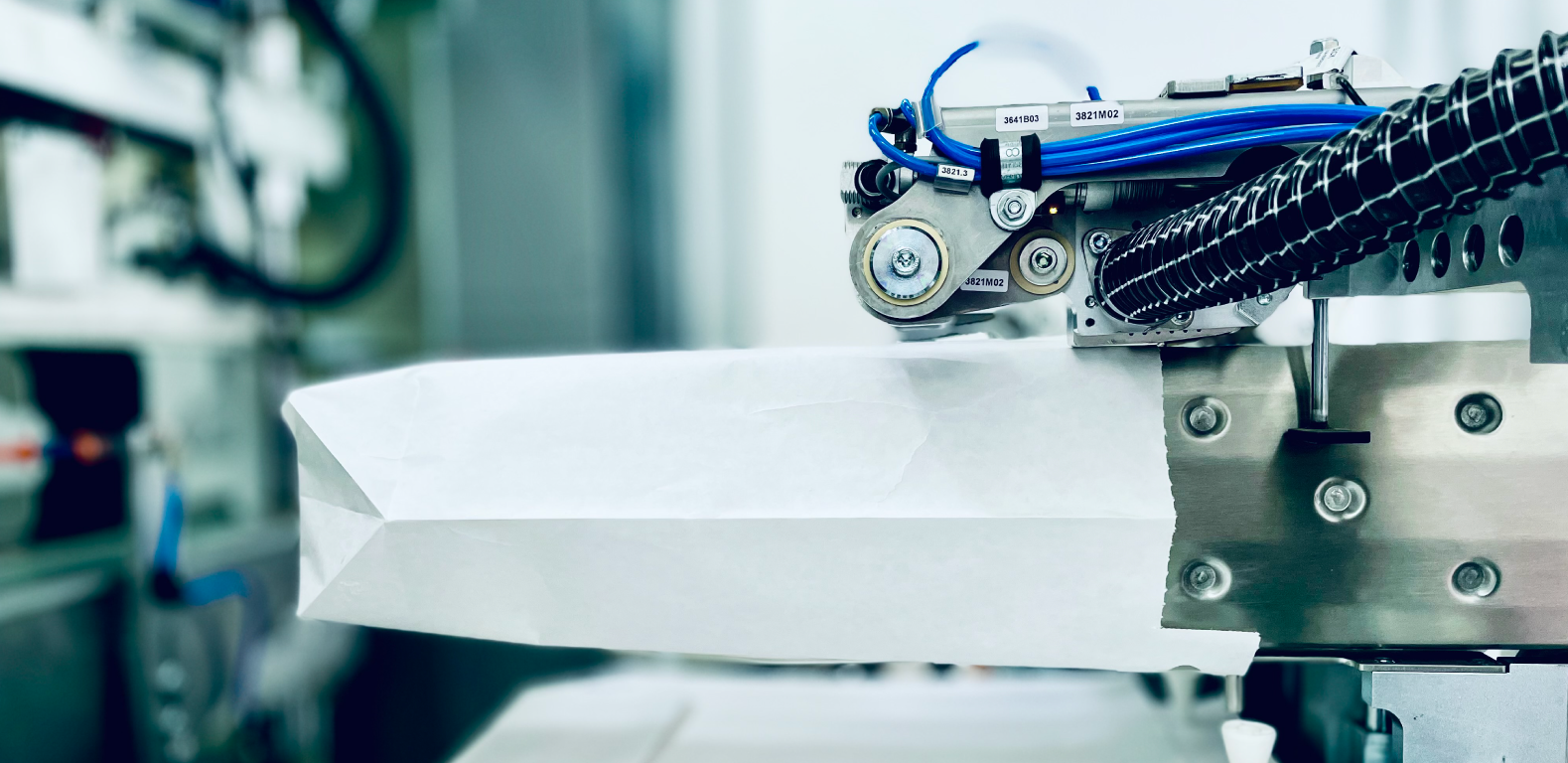

Thanks to precise product handling, even large or complex items can be managed without compromising their integrity. At the heart of the process is the shuttle system, which ensures every product reaches the bottom of the bag perfectly aligned, resulting in compact, uniform packaging with minimal waste.

The combination of robust construction and long-term reliability guarantees production continuity and safe operations — essential for high-volume, fast-paced markets.

For an in-depth look at primary packaging in Adult Care, read the dedicated article.

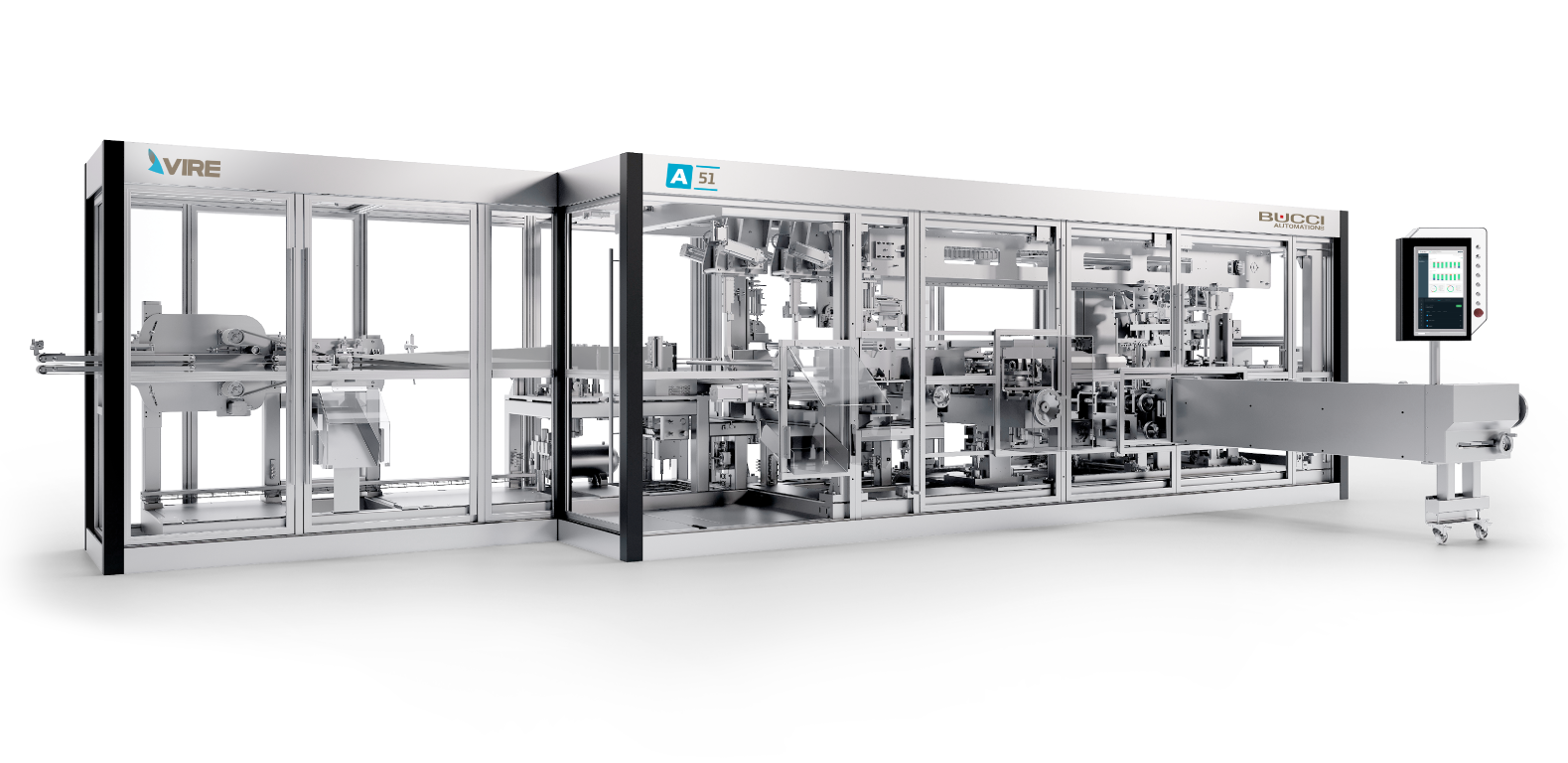

For Adult Care products, VIRE offers the single lane configuration, designed to ensure process stability, consistent quality, and reduced waste. The linear production flow guarantees control and continuity, achieving the ideal balance between productivity and efficiency.

Its compact footprint and simplified operations further reduce complexity and costs compared to more elaborate solutions. The result is reliable performance and long-term economic sustainability.

The incontinence market demands solutions that can handle a broad range of formats. VIRE machines meet this challenge with ease, adapting to all sizes — from S to XL — and to all product types: underpads, open diapers, pants, lady and men products.

To maximize flexibility, VIRE machines feature a quick format change system, enabling fast transitions between production types. Whether switching between Adult, Feminine, or Baby lines, setup times are minimized and production continuity is ensured, without compromising packaging quality.

Want to see how VIRE technology takes Adult Care packaging to the next level?

VIRE packaging machines are designed to optimize electric and pneumatic consumption, reducing operational impact while delivering both economic and environmental benefits. They can run 24/7 with minimal maintenance, ensuring consistent output and fewer stoppages.

For day-to-day operations, an intuitive interface simplifies parameter settings and speeds up alarm detection. This not only reduces training times for staff but also enhances operational safety.

With their combination of technical efficiency and cost-effectiveness, VIRE solutions are a reliable partner for companies aiming to reduce expenses without compromising quality or production continuity.

The Adult Care sector demands solutions that combine productivity, quality, and flexibility. VIRE machines rise to the challenge with advanced integrated automation, streamlining operations and minimizing critical variables on the line.

Automatic adjustments enable rapid adaptation to different formats, reducing downtime and simplifying changeovers. Automation also extends to process control, with digital supervision systems that constantly monitor parameters and ensure uniform standards across every cycle.

With these features, VIRE packaging machines deliver a measurable boost in productivity and provide strong support for meeting the demands of increasingly competitive markets with high-quality, cost-efficient packaging.

Interested in finding the configuration best suited to your needs? Request a personalized consultation with our Team.