In recent years, the European Union has stepped up its efforts to limit the use of hazardous substances in industrial processes—most notably through the REACH regulation (Registration, Evaluation, Authorisation and Restriction of Chemicals). This framework also extends to metals used in components for everyday applications.

Against this backdrop, the Lock & Key sector is facing a significant regulatory shift: the European Commission and ECHA are assessing potential restrictions on the use of lead-containing brass alloys.

The institutions’ direction is clear: to reduce the use of potentially harmful materials and promote alternatives aligned with ever-stricter environmental and health standards. This transition will significantly impact the entire supply chain, prompting to rethink their materials, processes, and technologies.

Want to understand how these new regulations could impact your Lock & Key business? Get in touch with our experts to explore the implications.

The Role of Lead in Lock & Key Manufacturing

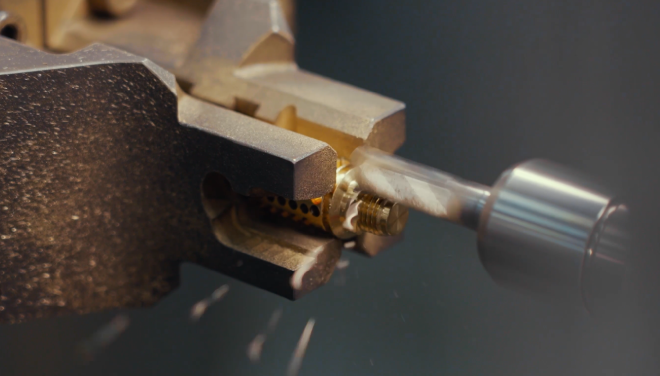

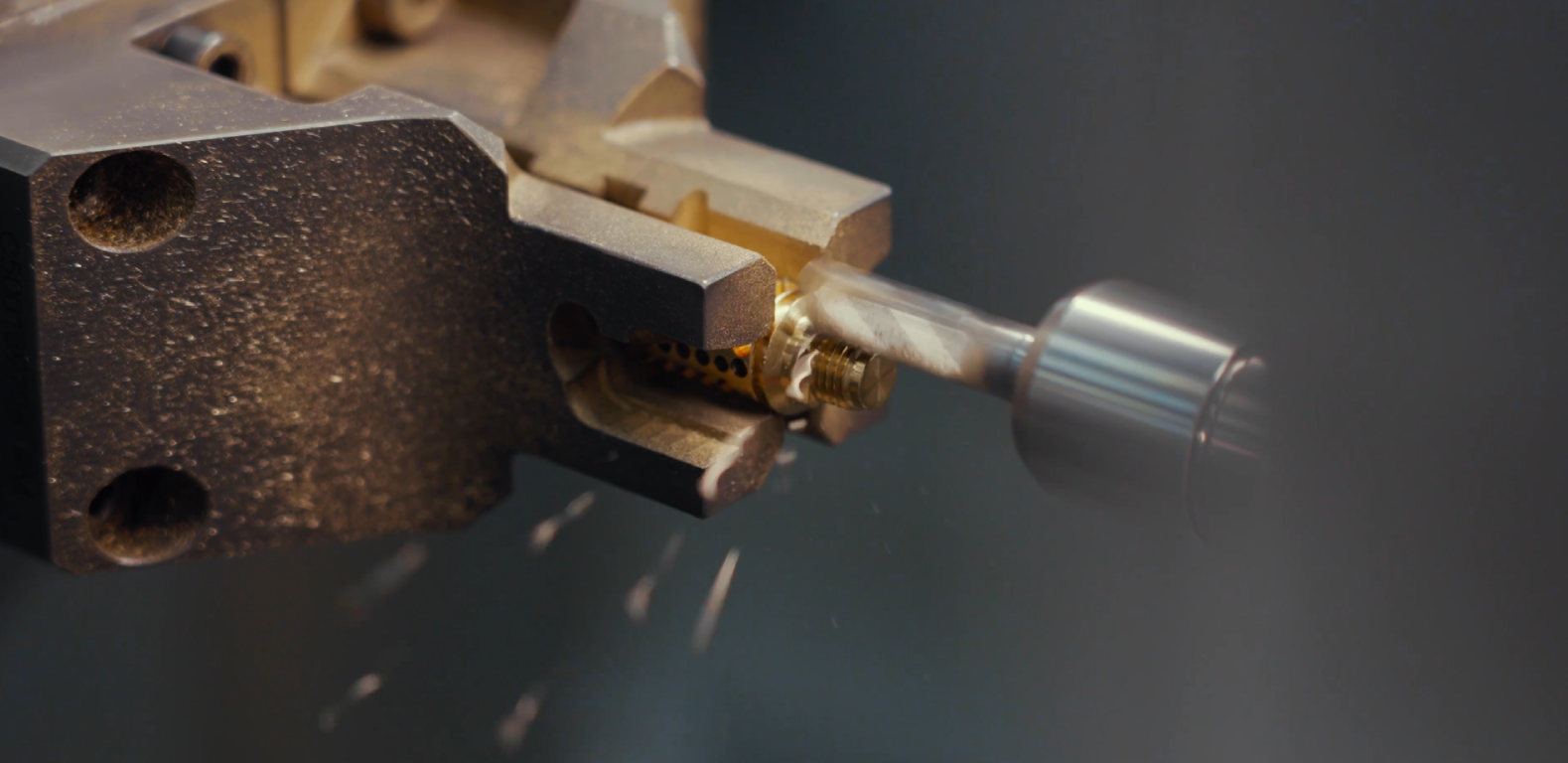

Historically, leaded brass has been used in the production of keys and locks to simplify machining processes. Lead functions as an internal lubricant, helping to reduce tool wear.

However, the EU is considering tighter regulations that could cap lead content in brass alloys at just 0.1%, requiring a fundamental rethink of the materials currently in use.

As a result, the Lock & Key sector is undergoing a complex transition that directly affects machining parameters and production process stability—leading to inevitably higher energy consumption and costs.

New Materials, New Production Processes

Lead-free alloys behave differently from traditional leaded ones, increasing machining complexity and impacting both tool performance and lifespan. This shift demands adaptation of processes and equipment, with heightened focus on process control and cycle stability.

The elimination of lead not only affects materials—it also fundamentally redefines production processes and requires a new balance among alloys, tools, and machining technologies. This challenge becomes a strategic opportunity for innovation to preserve efficiency, precision, and competitiveness.

The Machine Tool at the Core of the Lead-Free Transition

During this transition, the machine tool takes on a proactive role: it must handle more complex alloys, support testing cycles, and ensure consistent output even under non-standardised conditions.

Designing machines for this evolving context means anticipating change. This is the essence of Giuliani’s approach: delivering solutions that merge innovation with long-term reliability, guiding the industry toward safer, more sustainable materials.

Get your Lock & Key production ready for lead-free alloys—without compromising on productivity or quality. Discover TDRILL, Giuliani’s transfer machine engineered for the future of the industry.

Giuliani: Technological Partner in the Lead-Free Transition

In today’s shifting technological and regulatory landscape, Giuliani machines are already configured to handle lead-free alloys.

From advanced systems to compact machines, Giuliani’s solutions are already in use with alternative materials across diverse production environments.

The versatility of our solutions allows companies to embrace change without disruption, maintaining operational continuity and reliable performance—even with alloys that exhibit less predictable mechanical behaviour.

Giuliani reaffirms its role as a reliable technology partner for the Lock & Key industry—ready to support manufacturers in their transition to lead-free production.