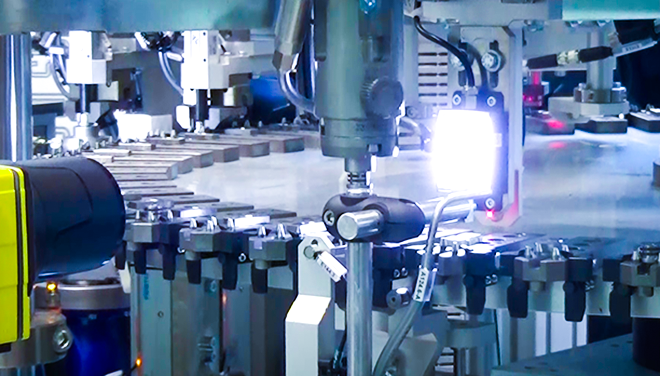

The world of industrial automation is changing. Web technologies are revolutionizing how machines are controlled, monitored, and integrated into business processes.

In a landscape increasingly oriented towards Industry 4.0 – and moving toward Industry 5.0 – supervision is no longer just a control system, but becomes a digital hub: flexible, scalable, and secure.

What is a Web Supervisor?

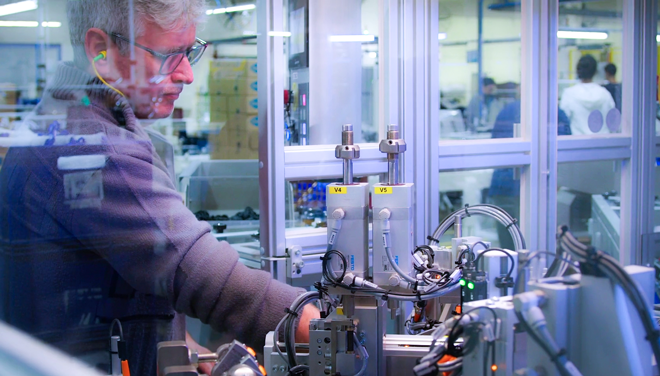

It is a responsive system, accessible from any device, designed to be user-friendly and highly customizable. The Web Supervisor completely replaces the old locally installed SCADA systems, offering a single platform that integrates operations, diagnostics, user interface, and multimedia content.

It is the brain of the line: a central PC, separate from the machines, that controls the entire system. And today, it can be developed with web technologies, transforming into a constellation of web-based software that adapts to any plant configuration.

Tangible benefits: why it’s a forerunner

1. Full accessibility:

• Viewable from smartphone, tablet, or PC: the system is fully responsive.

• The operational part is no longer tied to a physical push-button panel but lives in the software.

2. Easy integration:

• API exposure to communicate with external systems such as MES, ERP, CMMS.

• Ready for integration into 4.0/5.0 ecosystems.

3. Customization and modern UX:

• Interfaces designed with inspiration from the consumer world.

• Each user accesses only their relevant pages, thanks to advanced permission management.

• Specific views for each panel or machine area.

• Possibility to include multimedia operating instructions (images, videos, step-by-step guides).

4. Smart data visualization:

• Intuitive dashboards, modern graphics, and a focus on user experience.

• Advanced diagnostics, real-time monitoring, and machine-specific commands.

5. Total flexibility:

• The system is license-free: no commercial licenses are needed for PLC communication.

• Scalable: from a single device to complex plants.

• Standardizes technologies and components from different brands, overcoming hardware dependency.

6. Security & support:

• Encrypted data, maximum attention to cybersecurity.

• Internally developed by the Sinteco team: complete flexibility and constant support.