Operating in the micromechanics sector means designing and producing mechanical components of very small dimensions, often smaller than one millimeter. This discipline is used in multiple high-technology fields, such as watchmaking, precision mechatronics, consumer electronics, optics, medical and biomedical sectors, aerospace and defense, automotive and electric mobility.

The machining of micromechanical components requires handling very small dimensions, extremely tight tolerances, often complex geometries, and finishes with microscopic details. Ensuring repeatability and consistent quality is a challenge: vibrations and thermal variations can compromise the final result.

Precision, accuracy, and reliability are not only sector requirements but indispensable characteristics that every machined part must guarantee when used in highly technological devices.

This is exactly the level of performance also required from the bar feeder that supports a sliding-head lathe dedicated to the production of micromechanical components: it must ensure precision, accuracy, and reliability for optimal production performance.

In machining operations on sliding-head lathes for micromechanics, the bar feeder is a strategic ally in meeting the very high quality standards required.

To guarantee precision, reliability, and production continuity, it is essential to carefully evaluate the characteristics of the bar feeder, making sure it is designed to best handle the typical challenges of this sector.

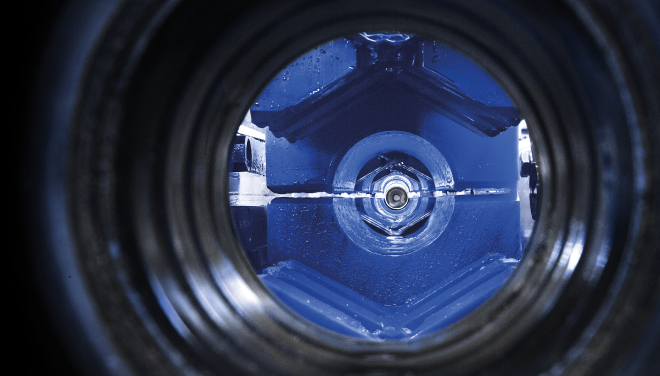

The bar feeder must be able to handle thin and lightweight bars, with diameters even below one millimeter, in a precise and reliable way. Every phase of the work cycle requires extreme delicacy and control: from the initial selection from the magazine, to positioning in the collet, through to recovering the remnant.

The selection process of the bar must be smooth, even with very small diameters that can stick together or accumulate. The presence of oily residues, extremely small dimensions, and other factors can interrupt the loading process: ensuring high reliability is one of the most complex challenges.

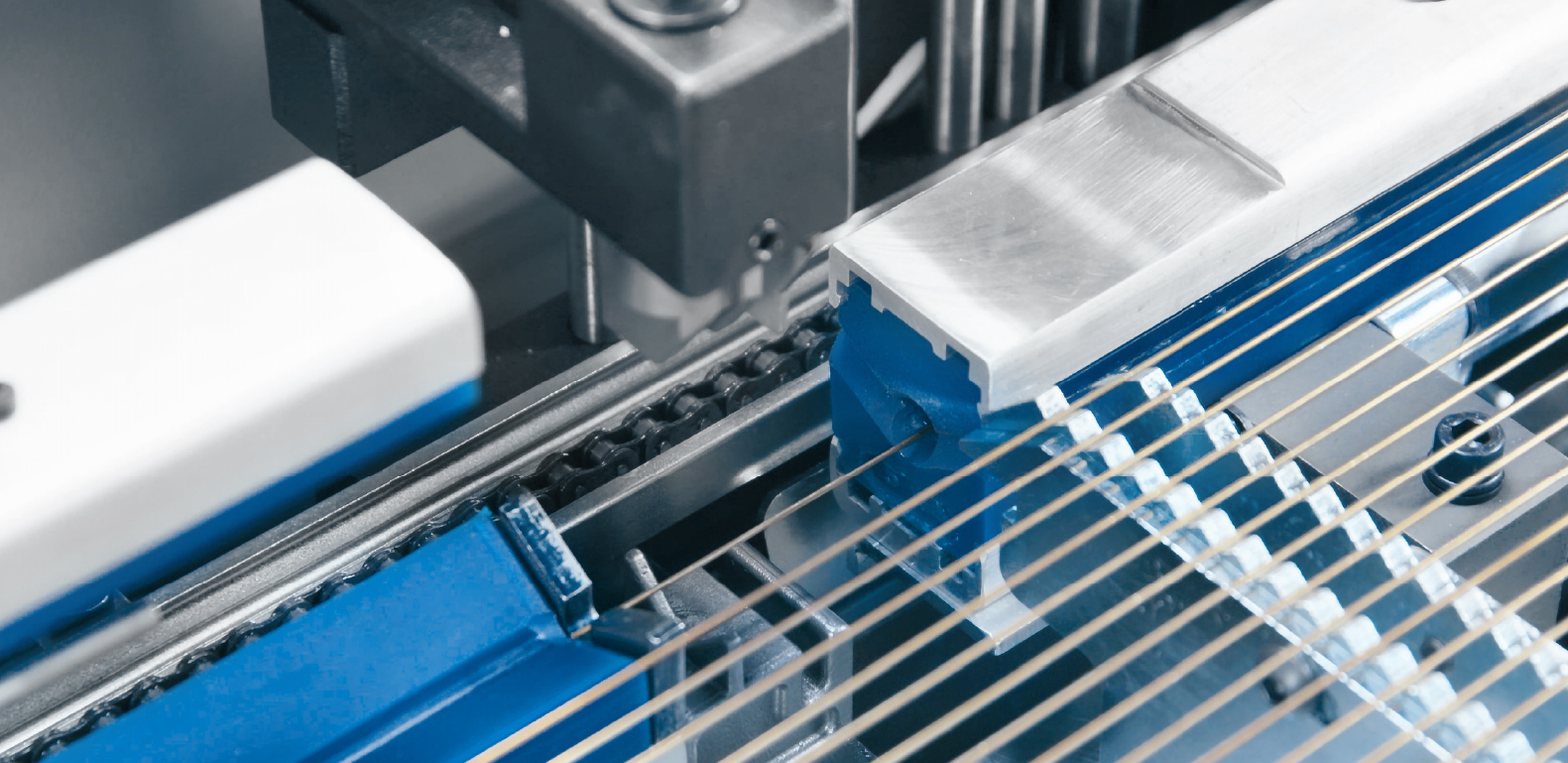

With lathes reaching speeds of 20,000–25,000 rpm, the bar feeder must keep pace without limiting the performance of the machine tool. Headstock pause times and bar change times must be reduced to a minimum to optimize cycle time and maximize productivity.

The efficiency of the bar feeder is measured by its ability to synchronize perfectly with the lathe, eliminating any hesitation that could translate into non-productive time. The bar feeder’s response speed becomes a decisive competitive factor.

The bar feeder must respond with great reactivity, even when the lathe operates at high accelerations. Imperfect synchronization can cause critical issues: bars slipping out of the collet, risks of material flexing, vibrations that compromise the final quality of the part.

The integration between bar feeder and lathe must be engineered to agilely follow every movement of the sliding headstock, ensuring stability even at the highest speeds.

In micromechanics, even the slightest vibration can compromise the quality of the finished part. The bar feeder must therefore have a high capacity to manage and absorb vibrations: guide channel, structural rigidity, and advanced support systems become fundamental elements.

The bar feeder must allow the full potential of the lathe to be exploited and achieve the precision required by micromechanical components.

The Iemca ELITE bar feeders for sliding-head lathes translate these requirements into concrete technical solutions, specifically designed to meet the needs of micromechanics.

Discover the Iemca ELITE range for micromechanics →

Iemca ELITE bar feeders easily achieve very high turning speeds without experiencing vibrations.

Discover the Iemca high-pressure solutions: compatible with sliding-head lathes, flexible, and highly energy efficient.

Production efficiency is guaranteed by cutting-edge technological solutions: ELITE bar feeders use Iemca Superfast Technology, which drastically reduces the lathe’s non-productive time.

These characteristics make Iemca bar feeders the ideal solution for those operating in micromechanics and requiring top-level performance, without sacrificing long-term reliability and precision.

Contact us now to discover how Iemca ELITE bar feeders can optimize your micromechanical production.